发布时间:2024-09-04

发布时间:2024-09-04

The Working Principle and Structure of Traction Elevator in Detail

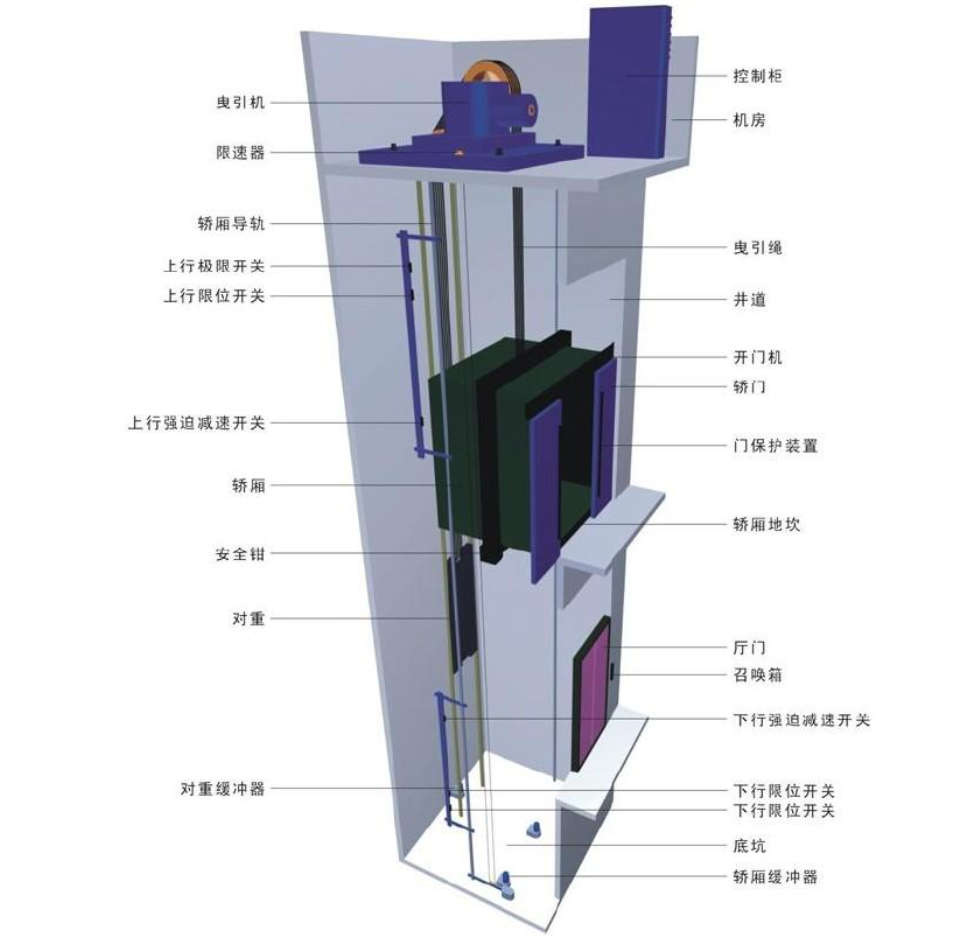

1. Traction Machine:The traction machine is the power source of the elevator and is responsible for driving the elevator car. It consists of an electric motor and a drum, and the motor drives the drum to rotate through a gear or belt transmission device. The wire rope is wound on the drum, and the rotation of the drum changes the tautness of the wire rope, thus controlling the rise or fall of the elevator car. The operation of the motor is precisely regulated by the control system to ensure the stability and safety of the elevator. In some advanced elevator systems, the traction machine may adopt gearless transmission to reduce friction and noise and improve operation efficiency.

1. Traction Machine:The traction machine is the power source of the elevator and is responsible for driving the elevator car. It consists of an electric motor and a drum, and the motor drives the drum to rotate through a gear or belt transmission device. The wire rope is wound on the drum, and the rotation of the drum changes the tautness of the wire rope, thus controlling the rise or fall of the elevator car. The operation of the motor is precisely regulated by the control system to ensure the stability and safety of the elevator. In some advanced elevator systems, the traction machine may adopt gearless transmission to reduce friction and noise and improve operation efficiency.

2. Steel Wire Rope:Steel wire rope is an important part connecting the traction machine with elevator car and counterweight. The wire rope is usually made of multi-stranded high-strength steel wire braid, which has strong tensile strength and abrasion resistance. One end of the wire rope is fixed on the top of the elevator car, and the other end is fixed on the counterweight. When the drum of the traction machine rotates, the wire rope is tightened and relaxed to raise and lower the elevator car. The quality and maintenance of the wire rope is crucial to the safety of the elevator. Regular inspection and replacement of the aging wire rope can prevent potential safety hazards.

3. Counterweight:Counterweight is a counterweight that matches the weight of the elevator car, usually made of heavy-duty materials and placed on one side of the elevator shaft. Counterweights are designed to balance the weight of the elevator car and reduce the workload of the traction machine, thereby improving energy efficiency and reducing energy consumption. The adjustment and configuration of counterweights are also critical to the operational stability of the elevator, and usually require precise calculations and adjustments according to the specific design and use of the elevator.

4. Guide Rails and Pulleys:The guide rail system in the elevator shaft provides stable vertical movement of the elevator car and counterweight, preventing them from swaying or deviating from the track during up and down movement. The guide rail can be U-shaped, T-shaped or other suitable shapes, and the material is usually chosen from high-strength steel or aluminum alloy to ensure its durability and stability. Pulley systems are used to change the direction of the wire rope, reduce friction and wear, and improve the operational efficiency of the elevator. Pulleys are usually made of wear-resistant materials and are precision machined to ensure smooth operation.

5. Braking System:The braking system is an important device to ensure the safe stopping of the elevator. It usually includes electromagnetic brake and mechanical brake to stop the movement of elevator car by applying braking force. The design of the braking system requires that it can respond quickly and reliably to the stopping command of the elevator to avoid any accidents caused by unexpected situations. In addition, modern elevator systems are also equipped with emergency braking devices, which can quickly perform braking operations to protect the safety of passengers when the elevator encounters faults or abnormal conditions.

6. Elevator Cabin:Elevator car is the part for passengers or goods to go up and down, and the interior is usually designed with control panel, lighting, ventilation and safety facilities. The design of the elevator car should not only consider the comfort of passengers, but also need to meet the requirements of barrier-free design, such as equipped with barrier-free handrails and low-level control panels. Various equipments and devices inside the car must meet the relevant safety standards to ensure the safety of passengers and normal operation of the elevator.

7. Shaft:The elevator shaft is the vertical passageway of the elevator system, providing space for the up and down movement of the elevator car and counterweight. The structure of the shaft is usually made of concrete or steel to ensure its solidity and stability. The guide rail system and other supporting structures inside the shaft need to be inspected regularly to ensure the smooth and safe operation of the elevator. The design of the shaft also takes into account ventilation and lighting to provide a good working environment.

8. Door System:The door system includes elevator car doors and floor doors, which are usually driven by motors for opening and closing operations. The linkage mechanism between the elevator car door and the floor door ensures the safe closure of the door during elevator operation, preventing passengers or goods from accidentally falling or being pinched. The design of the door system also takes into account the anti-pinch function, i.e. the ability to automatically stop or reverse the opening of the door when an obstacle is encountered during door closure. Modern door systems may also be equipped with sensors to improve safety and convenience.

9. Control System:The control system is the “brain” of the elevator, responsible for managing all the operations of the elevator, including up and down movement, speed control, stopping at the designated floor, etc. The modern elevator control system usually adopts computerized control system. Modern elevator control system usually adopts computerized control technology, which can carry out precise scheduling and fault diagnosis. Control systems also include displays and communication devices that provide real-time information feedback and status monitoring. Advanced control systems can also be integrated with building management systems to achieve intelligent scheduling and maintenance management.

Traction elevator is a widely used elevator system in all types of buildings, which is favored for its high efficiency, reliability and energy saving features. Below are the detailed benefits of incorporating a traction elevator:

1. High Efficiency and Energy Savin

(1.1)Reduction of Energy Consumption: The design of traction elevator utilizes the balancing effect of counterweight system to reduce the burden of traction machine. When the elevator rises, the downward movement of the counterweight helps to offset the weight of the car; when the elevator descends, the effect of gravity will assist in the downward movement of the car. This balancing reduces the power requirement of the motor, thus significantly reducing energy consumption.

(1.2)Optimizing Operational Efficiency:The control system of traction elevators can precisely regulate the running speed and direction of the motor, making the acceleration and deceleration process of the elevator smoother and further optimizing energy efficiency. This energy-saving effect is especially evident in high-rise buildings, where elevators need to handle more weight and longer lifting distances.

2. Smooth Operation

(2.1)Reduction of Vibration and Noise:The balancing effect of the counterweight system makes the elevator's lifting process smoother. Vibration and noise are greatly reduced during elevator operation, providing a more comfortable ride. This is especially important for elevators in high-rise buildings, which can effectively reduce the vibration impact on other parts of the building.

(2.2)Improved Passenger Experience:Smooth operation not only enhances passenger comfort, but also reduces the psychological discomfort caused by elevator instability. Especially in large commercial buildings or hotels, passengers have higher expectations of elevator comfort.

3. Longer Service Life

(3.1)Strong Durability:The core components of traction elevator, such as traction machine and wire rope, are made of high-quality materials, which are wear-resistant and fatigue-resistant. These components are designed with precision and manufactured with strict standards, which can withstand long time use and extend the service life of the elevator.

(3.2)Simple Maintenance:Due to the mature and stable design of the system, the maintenance of traction elevator is relatively simple, and regular inspection and maintenance can effectively avoid failures. Regular replacement of wire ropes and inspection of traction machine can maintain the reliability of the system.

4. High Adaptability

(4.1)Applicable to Middle and High-Rise Buildings:Traction elevator can be flexibly adjusted according to the height and load demand of the building, and is applicable to various building types from low to high rise. It is especially widely used in medium and high-rise buildings, and can meet the needs of elevators at different levels.

(4.2)Flexible Configuration:The elevator system can be configured according to specific needs, such as increasing the load and adjusting the speed. This flexibility enables traction elevators to meet the needs of different buildings and usage scenarios, including office buildings, commercial centers and residences.

5. High Safety

(5.1)Advanced Safety Devices:Modern traction elevators are equipped with a variety of safety devices, such as emergency braking system, door linkage mechanism, overspeed protection device, etc. These devices are capable of preventing malfunction or abnormal operation. These devices are capable of automatically activating protective measures in case of failure or abnormal situation to ensure the safety of passengers.

(5.2)Stable Operation Guarantee:The design and manufacture of traction elevators follow strict safety standards and specifications to ensure stable operation of the system. Maintenance and inspection procedures also help detect potential problems in a timely manner, further enhancing safety.

6. Easy Maintenance

(6.1)Easy Inspection and Repair:The design of traction elevator systems focuses on maintenance convenience. Routine inspections include the wear and tear of the wire rope, the operating condition of the traction machine and the functioning of the braking system. Maintenance and repair of the elevator system is usually more intuitive, and technicians are able to quickly locate problems and repair them.

(6.2)Reduced Failure Rate:Due to the high stability of the system, the failure rate of traction elevators is relatively low. Regular maintenance and inspection can effectively prevent potential problems, keep the elevator running normally and reduce downtime.

7. Reasonable Construction Cost

(7.1)Cost-Effective:Compared with some new elevator systems, the construction and installation cost of traction elevator is relatively reasonable. It provides a cost-effective option for most medium and high-rise buildings and commercial centers. Due to its mature technology and large-scale application, the costs of related components and services are also relatively low.

(7.2)Long-Term Cost-Effectiveness:Although the initial investment may be slightly higher, the long-term operation and maintenance costs are relatively low due to the energy efficiency and long service life of traction elevators, thus improving the overall cost-effectiveness.

Traction elevators are the ideal choice for many building projects due to their energy efficiency, smooth operation, long service life, strong adaptability, high safety, easy maintenance and reasonable construction costs. Its mature technology and reliable performance not only enhance passenger comfort, but also provide a stable and economical vertical transportation solution for buildings.

1.Ascent:When the elevator needs to ascend, the motor of the traction machine drives the drum to rotate, and the wire rope becomes taut, driving the elevator car to move upward. The counterweight will move downward to keep the balance of the system. The speed and steering of the motor are precisely regulated by the control system to ensure the elevator to rise and fall smoothly.

2.Descent:When the elevator needs to descend, the motor of the traction machine rotates in the opposite direction, the wire rope relaxes, and the elevator car moves downward under the action of gravity. The counterweight will move upward and continue to maintain balance. The reverse rotation of the motor is also precisely managed by the control system to ensure that the elevator decelerates and stops safely.

3.Balancing:The counterweight plays a key balancing role in the whole process, making the elevator car rise and fall more smoothly and reducing the work load of the traction machine. The design and adjustment of counterweight need to be calculated accurately according to the specific use of the elevator, in order to optimize the energy efficiency and operational stability of the elevator.

Overall, the components and working principles of a traction elevator are precisely designed and optimized for safe, efficient and smooth vertical transportation. The synergy of these systems and components ensures elevator reliability and user comfort.