发布时间:2024-09-19

发布时间:2024-09-19

Safety of Hydraulic Elevator vs Traction Elevator

The safety of an elevator is one of the most important factors to measure its advantages and disadvantages. When choosing the type of elevator, in addition to considering its performance, cost and applicable scenarios, safety is also a key indicator that cannot be ignored. This article will make a detailed comparison between hydraulic elevator and traction elevator, especially in terms of safety.

Safety of Hydraulic Elevator

1. Main Safety Measure

■ Buffer System: hydraulic elevator is usually equipped with pit buffer devices, such as spring or hydraulic buffer, which can effectively absorb the impact of the elevator car and reduce the injury to passengers in the event of an accident in the pit.

■ Hydraulic System Protection: The hydraulic system contains multiple safety valves, such as pressure relief valves, to prevent accidents caused by overpressurization of the system. In addition, hydraulic cylinders are equipped with seals to prevent oil leakage.

■ Door Locking System: Hydraulic elevators are generally equipped with an electrical door locking system to ensure that the doors cannot be opened during elevator movement, which improves safety during use.

2. Safety Hazards

■ Risk of Fluid Leakage: Leakage of the fluid used in the hydraulic system can lead to slipping on the floor or cause a fire, especially when maintenance is not done properly.

■ Power Failure Problem: In case of power failure, the hydraulic elevator may need to manually release the system to keep the elevator at the nearest floor to ensure the safety of the passengers, which may cause some inconvenience.

■ Pit Maintenance: The presence of a pit requires regular inspection and maintenance to prevent water from accumulating in the pit or other potential hazards.

Safety of Traction Elevator

1. Main Safety Measures

■ Saking System: The traction elevator is equipped with highly efficient braking system, such as safety brake, which can automatically lock the traction machine when the elevator is in abnormal situation to ensure that the elevator does not slide freely.

■ Counterweight System: Traction elevators use a counterweight system to balance the weight of the car and prevent safety problems caused by unbalanced loads. The counterweight system also has a safety device to prevent slipping.

■ Wire Rope Protection: The wire ropes of traction elevators are specially treated to provide high strength and wear resistance, and are equipped with a rope breakage monitoring device to ensure that safety measures can be taken in time in case of rope breakage.

■ Door System: traction elevators are usually equipped with multiple safety door locking systems to ensure that the doors cannot be opened before the elevator comes to a complete stop, thus improving the safety of passengers getting on and off the elevator.

2. Safety Hazards

■ Mechanical Failure: The mechanical structure of traction elevator is relatively complex and mechanical failure may occur, for example, the failure of the traction machine may cause the elevator to stop running. Regular maintenance and overhaul are necessary, but there is still a certain risk of failure.

■ Noise: Traction elevators are relatively noisy in operation. Although the noise itself does not directly affect safety, it may mask other potential mechanical problems, thus affecting the timely detection of faults.

■ Failure of the Electrical System: Failure of the electrical system may lead to failure of elevator control, especially when the electrical system is not properly designed and maintained. Modern traction elevators are often equipped with redundant systems to reduce the risk of electrical failure.

In terms of safety, hydraulic and traction elevators each have their own characteristics and potential risks:

Hydraulic elevators: their safety measures are mainly focused on the protection of the hydraulic system and buffers, and although the design is relatively simple, extra care is needed in terms of oil leakage and pit maintenance.

Traction elevators: equipped with more complex mechanical and electrical systems, their safety depends on the reliability of the braking system, wire rope protection and counterweight system, but the risk of mechanical failure and electrical system failure is also relatively high.

When choosing the right type of elevator, in addition to considering the technical performance and cost of the equipment, it is also necessary to conduct a comprehensive assessment of its safety performance to ensure that it can provide the maximum degree of safety in actual use. Reasonable maintenance schedules, regular inspections and high standards of installation quality are all key factors in the design and selection process to ensure elevator safety.

Performance Comparison Between Hydraulic Elevator and Traction Elevator

The performance of an elevator directly affects its performance in practical applications, including running speed, energy efficiency, comfort and other aspects. Hydraulic elevators and traction elevators have significant differences in these performance indicators and are suitable for different usage scenarios and needs. The following is a detailed comparison of the performance of these two types of elevators.

Running Speed

1.Hydraulic Elevator

Speed range: The operating speed of hydraulic elevators is generally low, usually between 0.5 and 1.0 meters per second (m/s). For the use of low-rise buildings (usually not more than 6 floors), the speed is sufficient, but in high-rise buildings may appear to be insufficient.

Reason: The lifting speed of the hydraulic system is limited by the capacity of the hydraulic pump and the design of the hydraulic cylinders, and the flow rate of the liquid limits the lifting speed of the elevator.

Applicability: Suitable for low-rise buildings or scenes requiring slower lifting speeds, such as homes and villas.

2.Traction Elevator

Speed range: Traction elevators run at a high speed, generally between 1.0 and 5.0 meters per second (m/s). High-end models can even reach over 6.0 meters per second (m/s), which is suitable for high-rise buildings and commercial use.

Reason: The traction elevator is faster because it transmits power through the traction machine and wire rope system, and the speed and power can be adjusted as needed.

Applicability: Suitable for high-rise buildings, office buildings, large commercial centers and other scenes that require faster lifting speed.

Energy Efficiency and Operation Cost

1.Hydraulic Elevator

Energy efficiency: The energy efficiency of hydraulic elevator is low. The work of hydraulic pump requires a lot of energy, especially in the case of frequent elevator lifting and lowering, the energy consumption is significant.

Running cost: Due to the low energy efficiency, the running cost of hydraulic elevator is relatively high. In addition, the fluid in the hydraulic system needs to be replaced regularly, which increases the maintenance cost.

Characteristics: The energy efficiency issue is less prominent when used less frequently in low-rise buildings, but for frequent use scenarios, the energy efficiency issue may affect the economy.

2.Traction Elevator

Energy efficiency: The energy efficiency of traction elevators is high. Energy consumption is relatively low due to the design of the traction machine and the high efficiency of the motor.

Running Costs: Higher energy efficiency results in lower running costs for traction elevators. Energy consumption and maintenance costs of the elevator are relatively low.

Characteristics: Suitable for scenes requiring high-frequency use, such as large office buildings and shopping malls.

Comfort and Noise

1.Hydraulic Elevator

Comfort: Hydraulic elevators are usually smoother in the lifting process, with less vibration and noise, providing a high level of comfort for passengers.

Noise: The working noise of the hydraulic pump is low and the overall noise control is good. The noise during elevator operation will not have a greater impact on the surrounding environment.

Characteristics: Due to the relatively simple design of the hydraulic system, the ride experience is comfortable, which is suitable for application scenarios with high requirements for comfort.

2. Traction Elevator

Comfort: The traction elevator operates at a high speed and the ride experience is usually comfortable, but it may generate certain vibration and noise when operating at a high speed.

Noise: The noise of traction elevator mainly comes from the operation of traction machine and wire rope. Although modern traction elevator has noise reduction design, the noise may be more obvious when it is used in high-frequency or operated at high speed.

Characteristics: It is suitable for high-frequency use scenarios with requirements on running speed, but noise and vibration management need special attention.

Applicable Scenarios

1. Hydraulic Elevator

Scenarios: Suitable for low-rise buildings (usually not more than 6 floors), residential buildings, villas, small commercial buildings, etc. Due to its lower speed and energy efficiency, it is suitable for less demanding occasions.

Advantages: lower installation cost, simple maintenance, high comfort.

Limitations: Not suitable for high-frequency use and high-rise buildings.

2. Traction Elevator

Scenario: suitable for high-frequency use and demanding places such as high-rise buildings, large office buildings, shopping malls and hospitals. Due to its fast speed and high energy efficiency, it is suitable for the demand of vertical transportation of large flow.

Advantages: fast speed, high energy efficiency, wide range of application.

Limitations: Higher installation cost, complex structure, possible higher noise.

There are significant differences in performance between hydraulic and traction elevators:

Hydraulic Elevator

Suitable for low-rise buildings, slower operation and lower energy efficiency, but better comfort and lower noise. Lower installation and maintenance costs, but inadequate performance in high-rise buildings and high-frequency use.

Traction Elevator

Suitable for high-rise buildings and high-frequency use scenarios, faster speeds, higher energy efficiency, but noise and vibration may be higher. Installation and maintenance costs are higher, but they are adaptable and can meet higher usage requirements.

When choosing an elevator, you need to consider factors such as the height of the building, frequency of use, energy efficiency requirements and budget to ensure that you choose the most suitable type of elevator.

Comparison of the Principles of Hydraulic Elevator and Traction Elevator

As an indispensable vertical transportation equipment in modern buildings, elevators are widely used in houses, office buildings, shopping malls and other places. According to different working principles and application requirements, elevators can be divided into various types, of which hydraulic elevators and traction elevators are two common types. In this article, we will make a detailed comparison of these two types of elevators to help you understand their respective characteristics, advantages and disadvantages and applicable scenes.

Hydraulic Elevator

1.Working Principle

Hydraulic elevator realizes the vertical movement of the elevator through the lifting and lowering of the hydraulic cylinder. The lift of the elevator relies on the hydraulic pump to press the liquid (usually oil) into the hydraulic cylinder, and the pressure of the liquid pushes the piston, thus driving the elevator car to rise or fall.

2.Advantages

Simple Structure:The main structure of hydraulic elevator is relatively simple, which is suitable for the situation where there is enough space on the ground floor of the building

Smooth and Comfortable:The lifting and lowering process is smooth, with less vibration and noise, making the ride comfortable.

Installation and Maintenance:Due to the simplicity of the system, hydraulic elevators are relatively easy to install and maintain, and the maintenance cost is also low.

3.Disadvantages

Slower Speed:Hydraulic elevators usually have a slower lifting speed and are suitable for lower floors (generally not more than 6 floors).

Occupying Space:Hydraulic systems require a large pit space, and the pit depth is usually around 1.5-2 meters.

Lower Energy Efficiency:The energy efficiency of hydraulic elevator is relatively low, because the hydraulic pump consumes a lot of energy when working.

4.Applicable Scenes

Hydraulic elevators are suitable for installation in low-rise buildings, such as low-rise houses, villas and some small commercial buildings. Due to its lower speed and the need for a larger pit, it is usually not suitable for high-rise buildings.

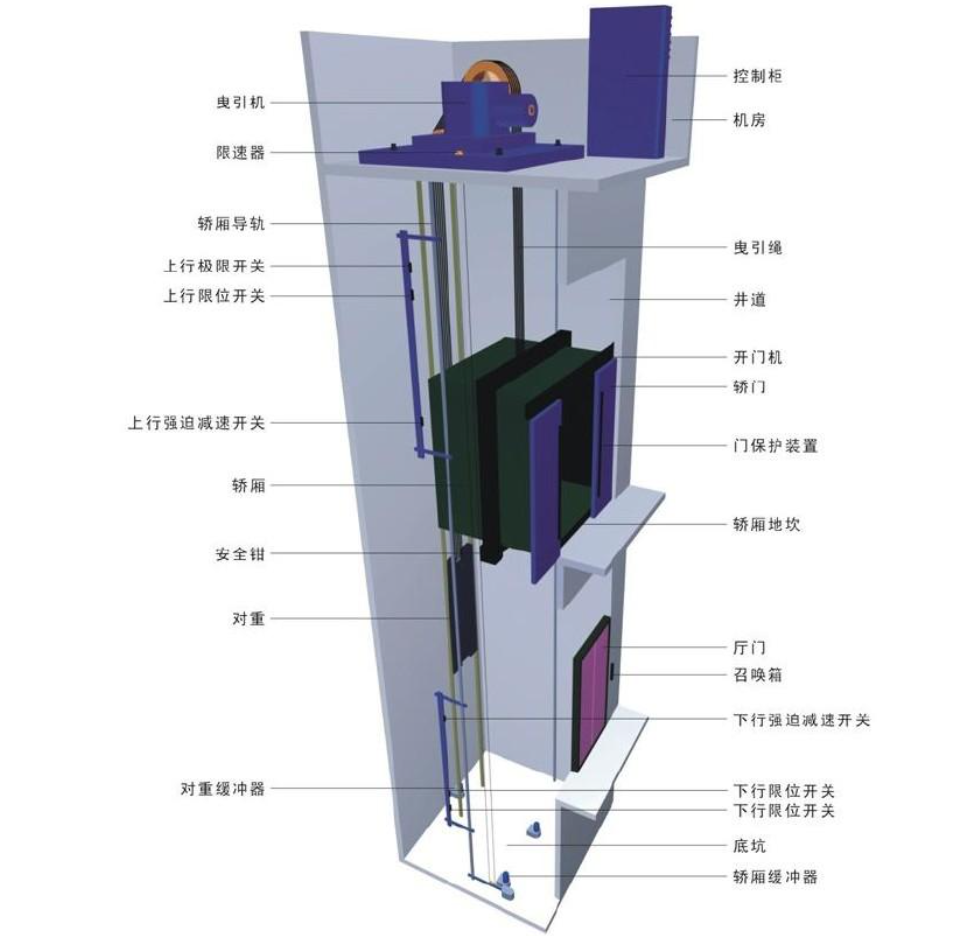

Traction Elevator

1.Working Principle

The traction elevator drives the wire rope or chain through the traction machine to realize the elevation of the elevator by going around a number of pulleys. The traction machine drives the pulleys through the electric motor, and one end of the wire rope or chain is fixed on the elevator car and the other end is fixed on the counterweight, and the elevator is lifted and lowered by adjusting the weight of the counterweight.

2.Advantages

Faster Speed:The traction elevator has a faster lifting speed, which is suitable for high-rise buildings and high-frequency use places.

Energy Efficient:Compared with hydraulic elevators, traction elevators are more energy efficient and consume less energy.

Occupying Less Space:It does not need a deep pit like hydraulic elevators, which reduces the demand for space on the ground floor of the building.

3. Disadvantages

Complex Structure:The structure of traction elevator is relatively complex, requiring professional maintenance and inspection, with higher maintenance cost.

Higher Noise:During operation, the noise of traction elevator is higher than that of hydraulic elevator, which may affect the quietness of using environment.

High Installation Requirements:The design requirements for the building are high, especially for the elevator shaft.

4.Applicable Scenes

Traction elevators are suitable for high-rise buildings, large commercial centers, office buildings and other places. They are widely used in various high-rise buildings due to their high speed, high energy efficiency and wide range of application.

Hydraulic elevators and traction elevators have their own advantages and disadvantages, and the selection of the appropriate type of elevator depends on the specific needs of the building and the usage environment. Hydraulic elevators are suitable for low-rise buildings and small venues due to their lower installation costs and ease of maintenance, while traction elevators are suitable for high-rise buildings and high-frequency use due to their faster speed and high energy efficiency. When deciding which type of elevator to install, you need to consider factors such as the height of the building, the frequency of use, the installation space and the budget.